PVC in Sports

Unmatched Performance: Why PVC is the Go-To Material in Sports

It is difficult to imagine a sporting world without PVC or vinyl. The material’s hard-wearing properties and long lifespan, as well as the fact that it can be used in all types of weather, are the main reasons why PVC is popular in the world of sports.

In addition, thanks to PVC’s versatility, designers have endless potential for creating designs that are stylish yet functional. And this applies to clothing, equipment and facilities alike.

Soft mattresses and shock-absorbent floors

PVC is an important component of clothing for both professional and recreational athletes. Furthermore, many sports are completely dependent on PVC: for example, a high jumper lands on a mat with a PVC surface. It is soft to land on, easy to clean and can cope with standing outdoors. In the world of water sports, there are kayaks made of inflatable, watertight PVC. This ensures water resistance and speed on the water.

In sports such as athletics, table tennis and badminton, it is crucial that the floor is made from a material that ensures athletes a soft landing, to avoid unnecessary injury.

Thanks to its water- and weatherproof properties, PVC is widely used in angling, both for sport and recreation. Long waders, for instance, are manufactured from PVC. In ski sports, the barriers skiers bump into are made of PVC too. But it is not only the athletes who benefit from the properties of PVC. Spectators in many stadiums across the world are protected from rain and baking sun by PVC canopies.

Flexible PVC ensures safety

Trampolines improve children’s motor skills and are an easy way of fitting physical activity into children’s busy lives.

Safety is also a priority: PVC safety mats are laid on top of the trampolines’ springs to protect bouncing children from falling on them. Moreover, PVC trampoline covers protect against the elements, significantly increasing its lifespan.

If we scale up, many bouncy castles are made of PVC, because it meets safety, functionality and durability requirements. Bouncy castles are made of several sections of fabric, welded together to be able to withstand massive pressure. Bouncy castle manufacturers and hire firms cannot compromise on safety in their products, and both tests and development projects indicate that there are no alternatives to PVC in this field.

PVC membranes cover padel courts

In the dynamic world of sports infrastructure, the PVC material is playing a pivotal role. Especially in the burgeoning field of padel, a sport gaining popularity for its engaging gameplay and social benefits.

The use of PVC in constructing padel courts represents a leap forward in material innovation, offering a blend of durability, flexibility, and environmental resistance that stands up to the sport’s demands. These structures that covered with a high-quality PVC membrane, are designed to ensure maximum airflow and player comfort, with sides that can be adjusted or opened to suit varying weather conditions.

The PVC membranes used are engineered to meet rigorous European standards for fire safety and are treated to resist mold, mildew, and UV damage, ensuring a long lifespan with minimal maintenance needs.

PVC in stadiums

As the most versatile plastic material, PVC, or vinyl, holds a prominent position in stadiums across Europe and beyond. This polymer is used in a variety of applications, including roofing membranes, artificial leather for massage tables and VIP seating, pipes for irrigation, drinking water, soil and waste management, sewage systems, cables, flooring, windows, signage, banners, player tunnels, and more. Explore the extensive use of PVC in some of Europe’s most iconic stadiums below:

Volksparkstadion – Hamburg, Germany

Volksparkstadion has a capacity of up to 57,000 spectators for league matches and is the home of Hamburger SV. The stadium also hosts international matches, concerts, and other sporting events. Completely rebuilt in 1998, it features a light, cable-suspended 35,000 m² roof that spans the entire spectator area. This roof is supported by 40 steel pylons positioned around the stadium behind the stands.

The structure includes an inner tension ring connected to an outer compression ring by 40 radially arranged cable girders. The span of these cable girders, and thus the roof depth, extends up to 72 meters. The roof covering is made from a PVC-coated polyester membrane, held in a double-curved shape by a secondary support structure.

Image: Reinhard Kraasch, License: CC-BY-SA 4.0 DE, CC BY-SA 4.0, https://creativecommons.org/licenses/by-sa/4.0, via Wikimedia Commons.

MHPArena – Stuttgart, Germany

Now called MHPArena, the original Neckarstadion was built in 1933 and has been renovated several times since. In 1993, a roof structure was added that consists of 28,000 m2 PVC-coated polyester roofing membrane suspended from an aesthetic steel frame that runs around the entire arena. This covers the grandstands completely and gives the stadium its significance.

In 2009 conversion into a football-only facility begun, which was finished two years later. For the retrofit, the athletic field was removed, the lawn lowered by 1.3 m and two new grandstands were constructed and placed closer to the pitch. To cover the new seating area, the already impressive roof was expanded by 6,000 m2. Now, 34,000 m2 of vinyl roofing help make MHPArena a world class stadium for VfB Stuttgart Bundesliga, German national team matches, and UEFA Euro games.

Image: Arne Müseler / www.arne-mueseler.com, CC BY-SA 3.0 DE https://creativecommons.org/licenses/by-sa/3.0/de/deed.en, via Wikimedia Commons.

VELTINS-Arena – Gelsenkirchen, Germany

The VELTINS-Arena in Gelsenkirchen is more than just a stadium; it’s a marvel of modern engineering. Originally named Arena AufSchalke, the arena features a sophisticated roof structure designed to accommodate 62,000 spectators.

Notably, the roof includes a PVDF-coated PVC membrane that contributes to its durability and aesthetic appeal. The movable section of the roof, positioned directly above the field, can be opened or closed in just 30 minutes, enhancing the stadium’s versatility.

The fixed sections of the roof required approximately 3,600 tons of steel, while the movable segment weighs around 600 tons. The truss construction, made from circular hollow profiles, spans an impressive 226 by 186 meters, covering the entire field and stands.

Image: Walter Koch, CC BY-SA 4.0 https://creativecommons.org/licenses/by-sa/4.0, via Wikimedia Commons.

Deutsche Bank Park – Frankfurt, Germany

The Waldstadion, currently known as Deutsche Bank Park is home to the football club Eintracht Frankfurt. It was originally opened in 1925 and has undergone several upgrades since. The most recent remodeling transformed it into a football-only stadium in preparation for the 2005 FIFA Confederations Cup and the 2006 FIFA World Cup. With a capacity of 58,000 spectators for league matches, it stands as the seventh-largest football stadium in Germany. The stadium was one of the nine venues for the 2011 FIFA Women’s World Cup, hosting four matches, including the final, and it is set to host five matches during the UEFA Euro 2024.

The stadium features a unique retractable membrane roof, earning it the nickname “the world’s largest convertible.” The fixed roof over the stands is a membrane-covered ring cable construction with an outer compression ring and two inner tension rings. The roof over the pitch includes an additional ring cable construction suspended between the two inner tension rings, with a central node acting as the hub. When the roof is open, the retracted PVC membrane is stored at this central node and can be extended in a few minutes along 32 radial cables using gliding carriages. This innovative design allows the stadium to quickly adapt to different weather conditions, enhancing the experience for spectators and players alike.

Image: Vasyatka1, CC BY-SA 4.0, https://creativecommons.org/licenses/by-sa/4.0, via Wikimedia Commons.

Volkswagen Arena – Wolfsburg, Germany

Volkswagen Arena is a football stadium in Wolfsburg, Lower Saxony, Germany. It serves as the home stadium for VfL Wolfsburg. Opened in 2002 and named after the automotive group Volkswagen AG, the arena has a capacity of 30,000, comprising 22,000 seats and 8,000 standing places.

One of the most striking features of the stadium is its sophisticated roof, a truss-supported membrane structure designed for durability and aesthetics. The roof consists of 32 radial trusses, each 40 meters in length, supporting a 15,000 square meter fire-retardant PVC membrane. This translucent membrane enhances the atmosphere within the stadium and supports the natural growth of the grass on the pitch.

In October 2017, the roof’s engineering was put to the test during Storm Xavier, which brought peak wind speeds of up to 178 km/h near Wolfsburg. Despite the intense storm, the Volkswagen Arena’s roof remained intact, showcasing its remarkable durability. The tensile cable structure, although it appeared to dance with the wind, withstood the forces without damage. VfL Wolfsburg assured fans that the roof could endure even stronger winds, highlighting the advanced engineering and resilience of the structure.

Image: Peter Olthof, Flickr, CC BY-ND 2.0, https://creativecommons.org/licenses/by-nd/2.0.

Planet Group Arena – Gent, Belgium

Architects chose 1.5 mm thick PVC membrane for the 13,000 m2 roof that covers the Planet Group Arena, also known as Arteveldestadion. The roof has a positive influence on the climate inside the arena, as it allows daylight to filter through while reflecting sunlight. The PVC membrane is also future-proof: it allows for a future installation of photovoltaic panels, and because of the high reflection of the membrane, the PVC will add 4% to the power output of the panels. The stadium is home of football club K.A.A. Gent.

Levante Stadium – Valencia, Spain

The newly renovated Ciutat de Valencia stadium is now one of the most modern stadiums in the Spanish league. First built in 1969, the stadium can receive up to 26,354 visitors and is home to Levante UD football club. As part of a project to renovate and upgrade the stadium, the building has been completely covered with a PVC coated polyester tensile roof structure.

Image courtesy of the European Council of Vinyl Manufacturers.

2012 Summer Olympics – London, United Kingdom

At the 2012 London Olympics, over 140,000 square meters of PVC were utilised in various applications, including tensile fabric structures and high-performance sports surfaces. This extensive use of PVC played a critical role in the functionality and aesthetics of the Olympic venues.

Significantly, some structures were completely dismantled and shipped to Brazil, where they were reused in football arenas for the FIFA World Cup 2014. This sustainable approach highlights the ongoing legacy and environmental consideration embedded in the planning and execution of the London Olympics.

Image: diamond geezer, Flickr, License: https://creativecommons.org/licenses/by-nc-nd/2.0.

Speed Skating Stadium – Inzell, Germany

In 2019, the Bavarian town of Inzell hosted the World Single Distant Speed Skating Championships. To create the world-class conditions required for this competitive event, the existing outdoor speed-skating track was upgraded with the construction of a high-performance, intelligent roof structure.

Designed with the interior climate concept in mind, the arena’s roof that is fitted with a PVC membrane stretched between the lower cords of the ten-meter high timber and steel trusses, ensures efficient, economic and sustainable day-today operations of the ice track.

The function of this PVC membrane is to reflect the ice’s own cold thermal radiation back onto the speed track to maintain the low temperature of the ice surface. Simultaneously, the PVC membrane maximises the quantity of diffuse daylight that streams into the stadium through the roof’s 17 large north-facing skylights.

Image courtesy of the European Council of Vinyl Manufacturers.

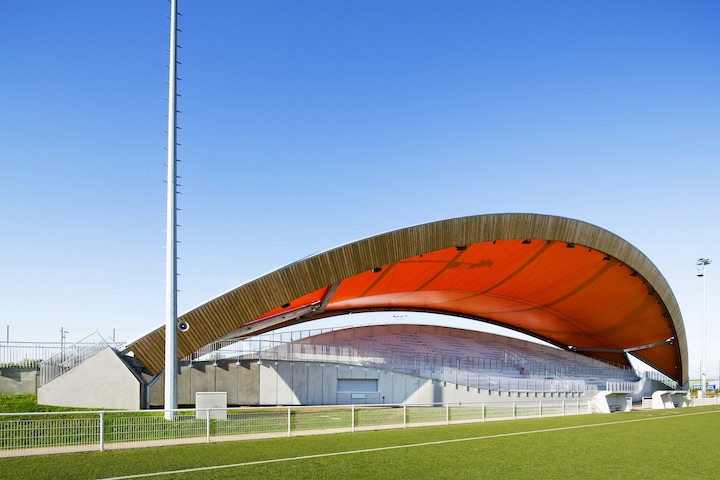

Football Stadium Salif Keita – Cergy-Pontoise, France

The structure of the tribune, which can welcome 1,000 spectators, is made of reinforced concrete. The roof, made of a tensile PVC membrane, protects the public from the sun and rain while allowing soft, natural light to enterThe roof structure constitutes two arched glulam beams, reinforced by steel tubes above the PVC membrane with its variable geometry that allows the central part to augment over the tribunes.

Image courtesy of the European Council of Vinyl Manufacturers.

Gamla Ullevi – Gothenburg, Sweden

The original Gamla Ullevi stadium, a beloved fixture in Gothenburg since 1916, was torn down in 2007 to make way for a new, modern arena. Two years later, in May 2009, the new Gamla Ullevi opened its doors, retaining the name to honor its historic legacy.

This state-of-the-art football temple serves as the home ground for the Gothenburg Alliance clubs IFK Göteborg, GAIS, and Örgryte IS. It also stands as the national stadium for the Swedish women’s national football team, hosting numerous memorable matches and events.

One of the notable features of the new Gamla Ullevi is its roof, which is covered with a PVC membrane. This modern roofing material ensures durability and protection against the elements, enhancing the stadium’s functionality and aesthetic appeal.

Allianz Riviera – Nice, France

PVC is essential to Allianz Riviera’s roofing: PVC tensile fabric covers the wooden frame, and PVC profiles keep photovoltaic panels on the roof in place. The architects explained that extenstive use of PVC enabled state-of-the-art design with environmental stewardship. The transparent PVC tensile fabric membrane for the façade, which lets daylight pass through, makes the building appear open and inviting, and PVC was chosen for the roof for its acoustic qualities. PVC was also chosen as it is long-lasting and recyclable, meaning that it contributed to the stadium being a positive energy building, and one of the first to bear the EnergyPlus label.

Roland-Garros – Paris, France

The prestigious Roland-Garros tennis complex in Paris welcomes thousands of visitors every year. Built in 1928, the Philippe-Chatrier Court is the venue’s main court, offering seats to 15,000 spectators. While the court has seen significant restructuring and improvement works since 2018, it recently underwent an even more dramatic transformation: the installation of a retractable roof to ensure matches can go on undisturbed in spite of bad weather or nightfall. The retractable roof, built for the 2020 tournament, constitutes 11 steel wings, clad with a translucent and waterproof membrane made of PVC. The roof covers a total surface equivalent to 1 hectare and requires around 15 minutes to be fully deployed.

Image courtesy of the European Council of Vinyl Manufacturers.

Parken – Copenhagen, Denmark

Parken Stadium in Copenhagen stands as a remarkable example of modernising existing buildings with PVC roofing membrane. The stadium features a 140-meter-long and 500-ton PVC membrane that can cover the entire venue within half an hour.

This innovative design ensures the stadium’s interior is well insulated, and the lightproof membrane prevents any external light from disrupting the desired lighting setup inside.

Parken serves as the national stadium for the Danish national football team and as the home ground for F.C. Copenhagen.

Learn more about PVC in stadiums in our leaflet: Vinyl in European Stadiums.