Recycling options

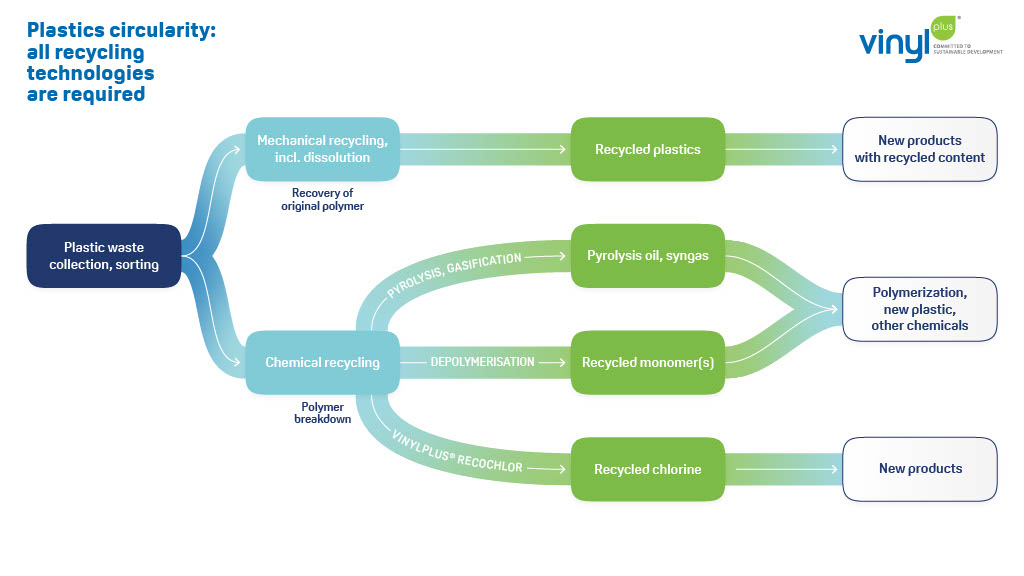

With increasing regulatory pressure to minimise disposal of plastics in landfill, and the obvious desire of the industry to be more sustainable, improving the scope of recycling technologies for PVC is important. There are two main options for the recycling of PVC waste: mechanical recycling and feedstock recycling. VinylPlus pays special attention to some of these technologies’ potential for an economically sustainable recycling of “mixed and difficult” PVC waste.

Mechanical recycling:

Mechanical recycling covers processes which do not break polymer chains. It is well suited to pre-sorted, single waste-streams. Within the mechanical recycling category, two subcategories are defined: conventional and non- conventional technologies.

Conventional technologies describe long established processes which usually sort, shred and separate components within the waste stream, resulting in granulated recycled PVC that can be used in the manufacture of new products.

Non-conventional technologies cover alternative processes that often use solvent based processes or pre-processing to access PVC from more difficult or complex waste streams. The PolyLoop process is an example.

Chemical recycling:

Chemical recycling is more suitable for unsorted plastic mixtures and waste streams containing composite materials. These processes involve thermal treatment of the PVC waste stream with recovery of hydrogen chloride that can then be returned to the PVC manufacturing or used in other processes. The hydrocarbon part of the PVC can be used to generate syngas (or synthesis gas – an industrially useful mixture of hydrogen and carbon monoxide) which can serve as a feedstock for chemicals production.

A specific chemical recycling process for PVC waste streams which are not suitable for mechanical recycling was developed in partnership with Solvay, Suez and Resolest. It uses the SOLVAir®flue gas emission control technology to neutralise hydrochloric acid gas created by the high temperature decomposition of PVC by sodium bicarbonate during incineration. The process of purification and material recovery from Flue Gas Treatment residues has been classified as recycling in the Best Available Technology (BAT) Reference Document for Waste Treatment (1). The recovered residual sodium chemicals are then purified by Resolest and the obtained NaCl used in a Solvay plant to produce soda ash. This supplementary recycling option helps to divert wastes from landfill and preserves natural resources by reducing the need to extract new raw materials (NaCl).

(1) Industrial Emissions Directive 2010/75/EU, Integrated Pollution Prevention and Control, section 5.5.1.3.1; October 2017