VinylPlus® Med Accelerates Sustainability in Healthcare

VinylPlus® has launched the collaborative project called VinylPlus® Med. Aimed at accelerating sustainability in healthcare across Europe through the recycling of discarded single-use PVC medical devices, the project brings together hospitals, waste managers, recyclers and the PVC industry.

COVID-19 has highlighted the crucial role played by single-use plastic medical devices in the prevention and control of infection in hospitals. The surge in the need of such disposable items has shed light on the challenges of properly managing and discarding them after use. Properly sorting and recycling the non-infectious plastic waste can both significantly reduce the environmental impact of hospitals and their operational cost.

What’s new?

VinylPlus® supports VIL and Denuo in the recycling of medical materials

VinylPlus® proudly announces its collaboration with the Select4Care project, aimed at increasing the recycling volumes of medical PVC in Belgium. Through enhanced medical plastic waste collection and sorting logistics, spanning from hospitals to recyclers and...

Grand Hôpital de Charleroi launches PVC recycling at three sites

We are happy to announce the launch PVC medical waste recycling at three sites of the Grand Hôpital de Charleroi: Notre Dame, St Joseph, and IMTR. 15 tonnes/year of waste from the operating rooms and intensive care departments will be kept out of incineration....

Recycling PVC medical tubing cuts greenhouse gas emissions by 25% compared to incineration

Hospitals are looking for ways to reduce their climate impact and consumption of resources. Since 2022, the VinylPlus Med recycling scheme has help Belgian hospitals to sort their DEHP-free PVC-based medical waste, which is turned into hospital wall covering and other...

VinylPlus helps hospitals sort their PVC medical waste stream

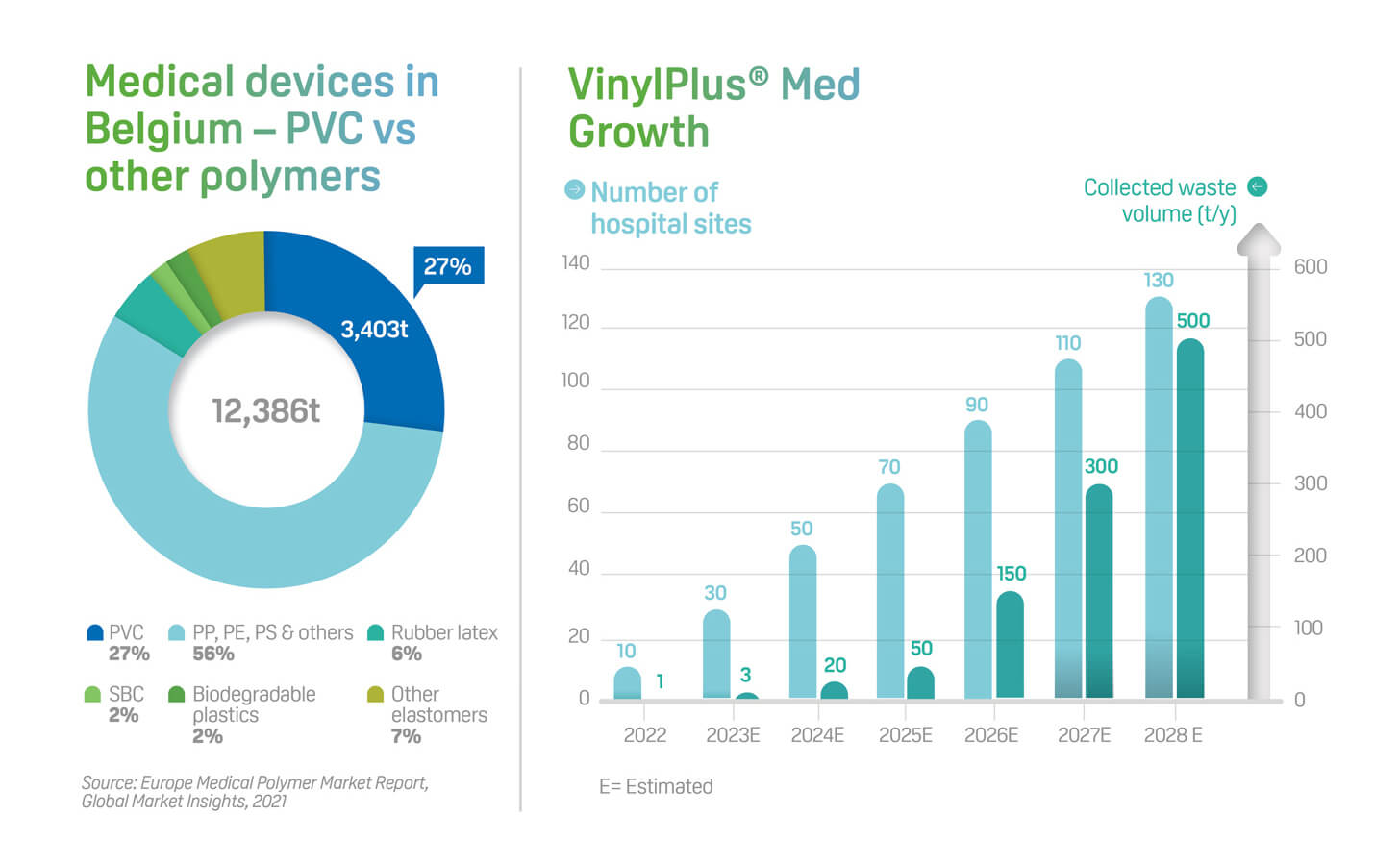

PVC is the most common plastic used in life-saving disposable medical devices including oxygen and anaesthetic masks, tubing, IV and dialysis bags. Many of these devices, used once with no contact with patients or in contact for a short period of time on non-infectious patients, can be recycled.

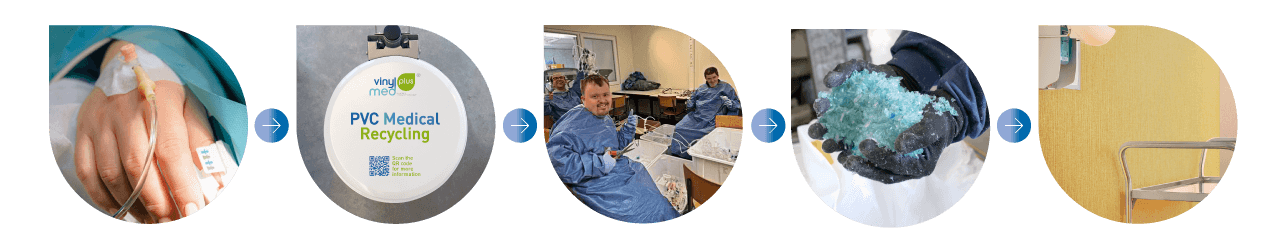

Building on the success of the VinylPlus-funded RecoMed recycling scheme, VinylPlus® Med developed a recycling scheme for single-use PVC medical devices in Belgium to help hospitals sort their PVC medical waste stream. The scheme, launched in February 2022, focuses on clean and REACH-compliant PVC waste that can be recycled into a wide range of value products marketed across Europe.

The project partners with Raff Plastics as the recycler, Veolia as the logistics & waste management partner, and De Loods Nekker as the social partner and waste hub for dismantling non-PVC items. VinylPlus® Med counts around 25 hospitals, all located within a radius of 200 km, to minimise transport distances and thus mitigate carbon footprint.

From disposable medical devices to durable hospital wall covering

The high quality, colorless medical PVC waste collected at VinylPlus® Med hospitals can be turned into a wide range of useful products used in the healthcare sector. An example is vinyl wall covering, which can incorporate regrind PVC obtained through an environmentally benign process. Vinyl wall covering is hygienic, dimensionally stable and resistant to chemicals. Due to its durability and shock-absorbent properties, vinyl is ideal for walls which have to be protected from collisions with beds and other types of hospital equipment. Vinyl also helps to create a holistic architectural design expression.

Scanner ensures only REACH-compliant waste is recycled

It is crucial for the success of VinylPlus® Med that only REACH-compliant, DEHP-free PVC is recycled. To meet this objective, a cost-efficient portable near-infrared (NIR) scanner has been developed. By use of artificial intelligence, the scanner can detect the presence of PVC and DEHP in the waste stream. This scanner can be used on PVC waste streams from other sectors, thus facilitating an easy sorting of flexible PVC.

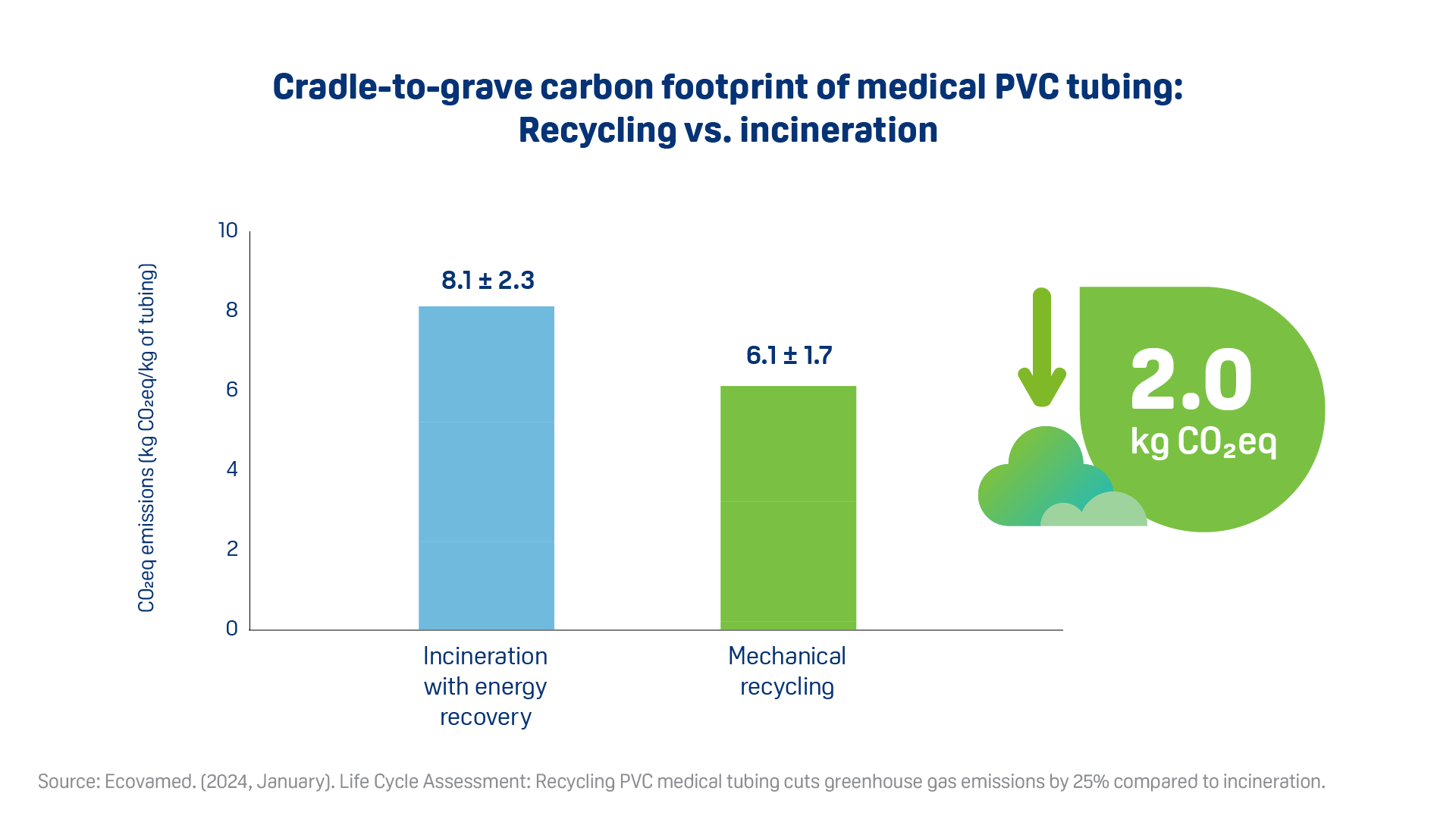

Recycling PVC medical tubing cuts greenhouse gas emissions

To quantify the carbon savings achieved through VinylPlus Med’s recycling efforts, French consultancy Ecovamed conducted a Life Cycle Assessment (LCA) on PVC-based medical tubing in Europe. This evaluation estimated the carbon footprint from start to end, adhering to the GHG Protocol standard, and analysed two scenarios for the tubing’s end-of-life:

- Incineration with energy recovery and acid flue gas treatment

- Recycling of medical tubing by mechanical grinding in Belgium, with an 80% yield, and production of wall coverings with the recycled material

On a cradle-to-grave basis, recycling allows to reduce by 25% the greenhouse gas emissions of a PVC medical tubing on its full life cycle, as compared to the scenario with incineration, corresponding to 2.0 kg CO2eq avoided per kg of tubing.

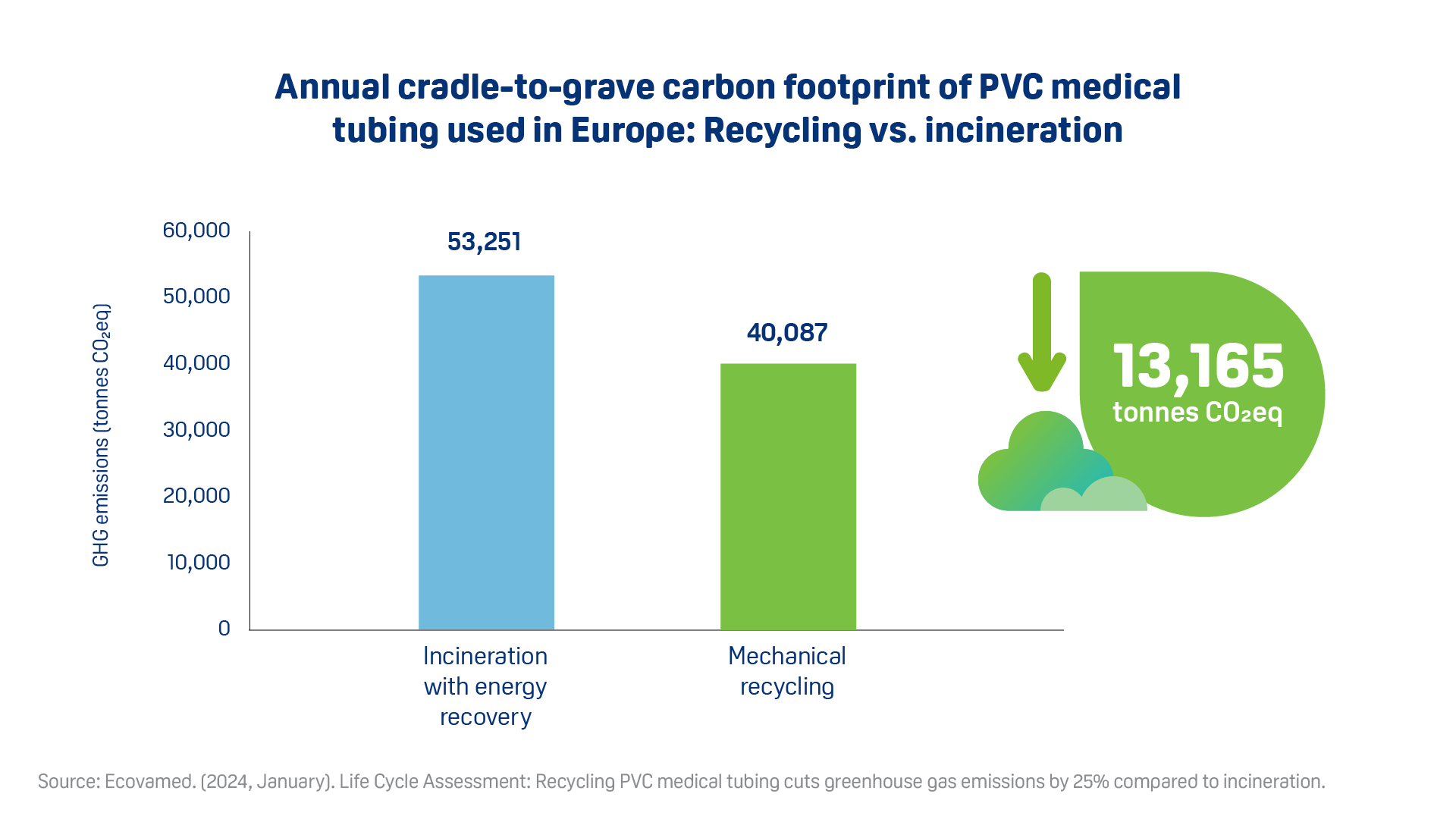

6,200 tons of plasticised PVC being used each year in Europe to produce medical tubing. The annual greenhouse gas avoided emissions if all medical tubing would be recycled are 13,165 tonnes CO2eq emissions, which is equivalent to 7,438 back and forth flights for 1 passenger between Paris and New York.

A growing network

More and more hospitals are joining the VinylPlus Med scheme. Discover which in the map below.

Hospital in the VinylPlus® Med scheme

Logistics & waste management

Waste dismantling hub

Plastic recycler

Our partners

Raff Plastics

Raff Plastics, being ISO 9001 and EucertPlast certified, has pioneered high-quality recycling of vinyl in Belgium since 1981 and produces 50000 tonnes of plastic recyclate each year.

Discover why Raff Plastics became a VinylPlus® Med partner in the interview with Co-Owner and Manager Carolina Van der Perre.

De Loods Nekker

Our social partner and waste dismantling hub, De Loods Nekker, carefully removes non-vinyl parts from medical devices, ensuring that clean, high-quality vinyl is sent directly to recycling. This meticulous sorting process not only optimises material recovery but also strengthens the social and environmental pillars of sustainability.

Veolia

Hospitals in the VinylPlusMed recycling scheme

What they say about us

VinylPlus Med mentioned as an example of already existing initiatives in Belgian hospitals to collect and recycle disposables.

CHU St Pierre announced that the hospital could collect 150 kg PVC in 3 months and that VinylPlus Med will be applied in all departments by end-2023.

Le recyclage des déchets hospitaliers en PVC prend son envol en Belgique: “Notre hôpital est, comme bien d’autres, un gros pollueur”

Le PVC est le plastique le plus largement utilisé dans les dispositifs médicaux jetables : masques, tubulures… Le projet VinylPlus Med, qui vise à trier les applications médicales en PVC pour les recycler, vient d’être lancé chez nous. Objectif : 1 000 tonnes par an !

Bronze in Circularity category: VinylPlus for its ‘collection and recycling process targeting non-infectious PVC medical consumables’

VinylPlus Med nominated in top 3 of the Circular Economy/Large Companies category

VinylPlus Med, un projet commun de recyclage des déchets médicaux en équipement hospitalier.

Trois structures unissent leurs forces pour accroître la durabilité dans le secteur des soins de santé en Belgique. A terme, le projet collaboratif VinylPlus Med devrait permettre d’éviter l’émission de 2.000 tonnes de CO2 par an grâce au recyclage des déchets médicaux.

More than 10 years of medical PVC recycling

Already today, PVC medical devices are recycled in eight countries around the world. It started in Australia in 2009 and has spread to over 250 hospitals and health clinics in the US, Canada, South Africa and elsewhere. The clean, high-grade recyclate is turned into useful products. In South Africa, IV bags become school shoes that enable education for impoverished children. In Australia, the recyclate is used for industrial and garden hoses and ergonomic mats that improve the work environment. Read more about medical PVC recycling at website of PVCMed Alliance.